A. Bulking of Sand

The volume of a given quality of Sand varies according to its moisture content. If the sand is wet, particles get a covering of water, which due to surface tension, keeps them separately and thus causes an increase in volume known as “Bulking“.

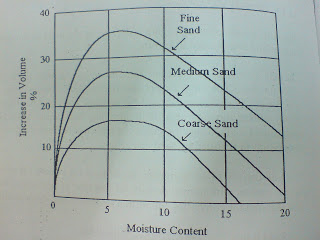

Bulking increases gradually with moisture content and the increase in volume may reach ~35% by volume at 5% – 6% moisture content by weight. It then decreases down to zero, when the quantity of water becomes more than ~25% (as if they are fully compacted).

Therefore, the measurement of sand by volume should take into account its moisture content periodically in a day (after every 04 hrs.). The Bulking increases with fineness of sand, because of large surface area contributed by fine particles for the same volume contribution.

B. Why Should One Determine Bulkage?

The purpose of determining the percentage bulking of sand is to know the amount of change in volume of sand, when it is wet, so that necessary correction can be applied in quantity while measuring & adding sand by volumetric method(be it in concrete of mortar/plaster)

River sand is dredged from river bed making it wet. Since river sand contains small size particles (which has greater surface area), it hold water for long, even when dispatched to site after days of dredging. Bulkage of sand occurs due to presence of water thus increasing its volume in proportion to its moisture content. Water present in sand can influence fresh and hardened properties of concrete and mortar.

Fresh Concrete/Mortar: Workability increases as there is an increase in the water content. Excess water content leads to Plastic shrinkage cracks

Hardened Concrete/Mortar: Strength of Hardened Concrete/Mortar reduces.

If due allowance is not given to sand bulkage (moisture content) in concrete and mortar design proportions, the desired end results can’t be achieved.

C. Determination of Bulkage

Procedure:

Bulkage of wet sand is determined by filling a graduated cylinder up to a certain mark with the wet sand and the volume is noted, Say V1.

The cylinder is then filled with water to submerge the sand sample completely and shaken . The volume of sand is again noted, Say V2.

Calculation:

Therefore percentage Bulkage of sand (Z) =(Decrease in volume / Final Volume) X 100

Bulkage (B) = (V1 – V2)/ (V2) x100

Volume (Quantity) of sand need to be increased by bulkage present in sand i.e. by B%

D. Application in The Field

A. Adjustment in Sand Where Volumetric Batching is Being Carried Out

- If the volumetric batching is used for concreting, then the volume of sand is generally measured by boxes at site. If the bulking is found to be 20%, the volume of sand has to be increased by 20%.

Suppose the size of box (measuring gauge/pharma) for sand is 30 cm x 40cm x 30cm depth.

Therefore, volume of dry sand V2 = 36,000 cm3 (36 liters)

Bulking of sand = V1 – V2 /V2

If volume of wet sand to be mixed in the concrete is V1

Then 20 % = (V1 – V2 )/V2 OR 0.20 V2 = V1 – V2, V1 = 1.20 V2

Adjustment in sand content where volumetric batching is used

Hence the quantity of wet sand has to be increased by 20% by volume i.e. 36,000 x 0.20 = 7200 Cu.cm

Depth of additional sand in box to be added = 7200 / 30 x 40 (area of box) = 6 cm

A mark should be made in the box for 6 cm depth from bottom.

The quantity of sand shall be one full box and an extra depth of 6 cm of sand in the same box has to be added.

- The same to be done if volumetric batching is used for external plaster, assuming a ratio of 1:4

The quantity of sand shall be four full box and an extra depth of 6*4(24) cm of sand in the same box has to be added.

B. Adjustment in Water Content Where Volumetric Batching is Used

Adjusted water quantity (in concrete) = Quantity of water as per design mix – (1+W) x Moisture content

Bulkage Curve Method

This is very effective & quick method of determining the moisture content at Field without any waiting period involved in drying the sand.

- A sample of dry sand is taken and 1% water by weight is added and thoroughly mixed. Bulkage of this mix is determined by filling a graduated cylinder upto a certain mark with the sand and the volume is noted, Say V1.

- The above procedure is repeated to determine bulkage at 2%, 3% … upto 35% of water content.

- A graph can be plotted between moisture content

Indicative bulkage Curve

and bulkage with different percentages of moisture content.

At site, the same graph can Indicative Bulkage Curve be used to determine moisture content indirectly from the corresponding bulkage value, after bulkage is determined by standard method the quality of sand sample is more or less same as used in laboratory for making a calibration curve.

C. Adjustment in Sand Content Where Weigh Batching is Done

Suppose the mix design for M-25 grade concrete is as follows

Cement=320 kg, Sand = 630 kg, 10 mm aggregate = 600 kg, 20 mm aggregate = 630kg &

Water =170 Litres.

If the percentage of moisture content in sand at site is found to be 4% and the aggregates are weight batched, then the following adjustments are to be made in 1 cum batch of concrete.

If 96 Kg is the quantity of dry sand in 100 Kg of wet sand (4kg being water, 4% moisture content)

Hence for 630 Kg of dry sand = (100/96) x 630 of wet sand to be used. = 656.25 Kg

Hence the quantity of wet sand has to be adjusted to 656 Kg (because of site condition) to get the required dry sand quantity of 630 Kg (designed quantity assuming dry sand)

630 Kg of wet sand will contain 4% water.

Therefore, quantity of free water = (4/100) x 630. Say 25 Liters.

Therefore, the quantity of water to be added in the mix is follows

Original water content – Excess water in sand = 170 Kg – 25 Kg Say = 145 Kg or liter

Hence the quantity of water has to be reduced to 145 Liter (water reduced by 25 liter from designed amount 170, as wet sand of 656 kg will have the same amount of water).

Due Consideration Of Moisture Content In Sand To Be Given In, Concrete/Mortar Mix Proportion To Arrive At Designed Performance/Result.

(+91) 7249196273

(+91) 7249196273