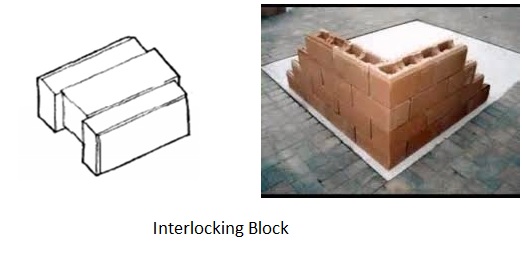

Dry stacked interlocking masonry system, as the name signifies is a system of arranging masonry blocks in such a way that they interlock each other, this is a mortar less system. The blocks are arranged in stretcher bond usually.

If mortar is to be used, they are only laid in the bottom two layers above the damp proof course and the top two layers near the roof edge else the cement paste is grouted. But the strength of this mortar system is not dependent on the mortar used instead it is based on the interlocking of the blocks and their self-weight to resist external loading.

Types of Dry Stacked Masonary System

There are many types of interlocking blocks available based on the material used they are,

- Fly ash interlocking blocks.

- Cement concrete interlocking blocks.

- Rice husk cement blocks.

- Soil cement interlocking blocks.

Another classification of interlocking blocks is available based on its size which is given below,

- Full blocks – 150 mm : 300 mm : 100 mm

- Half blocks – 150 mm : 150 mm : 100 mm

- U shaped blocks or channel blocks – 150 mm : 300 mm : 100 mm

- U shaped half blocks – 150 mm : 150 mm : 100 mm

Strength of Interlocking Masonary Wall

Since mortar is not used we may think the strength of walls built by these interlocking blocks will be less comparatively. But to the contrary, this system can be used to build effectively strong and durable structures. The interlocking blocks arranged in stretcher bond provide good finish and aesthetic view in the facing direction of the wall thus plastering is also not required.

Advantages of Dry Stack Interlocking Masonary system

There are many advantages of using dry stacked interlocking masonry system, some are stated below

- This is a more economical way of construction of walls.

- The time of construction is reduced.

- This type of construction does not require skilled labour for erection.

- Plastering and finishing is not required which in turn reduces the workmen required.

- The cost of cement mortar is eliminated.

- The problems encountered while using mortar like inadequate bond and mortar cracking which in turn provides room for water seepage is eliminated completely in this system.

- Quality control is more effective, since the blocks are precast.

- They have higher compressive strength and bearing capacity when compared to conventional blocks.

- These interlocking blocks are eco-friendly since no burning is required during manufacture.

Assembling of Interlocking Masonary System

These interlocking blocks can be assembled in three ways, they are

- Plain dry stacking

- Providing surface bonds

The plain dry stacking system can be used in retaining walls, partition walls, but it is not suited for human occupancy.

The surface bonding system if plastered and finished can be used in load bearing walls of two storey buildings. The walls can also be fibre reinforced or supported on sides with meshes to make it more durable.

In grouting system the walls are internally filled with cement grout increasing its strength, thus they are in par with conventional reinforced masonry systems used for buildings with three or more storeys.

Specifications of Interlocking Masonary System

BED: The lowered bottom surface of the interlocking block..

RIDGE: The raised upper surface of the interlocking block

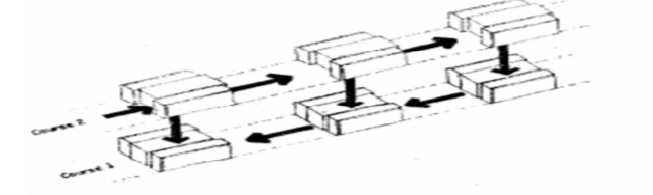

INTERLOCKING PATTERN: The bed of one rock is kept over the ridge of other rock and it is interlocked

Ridge to Bed Interlocking

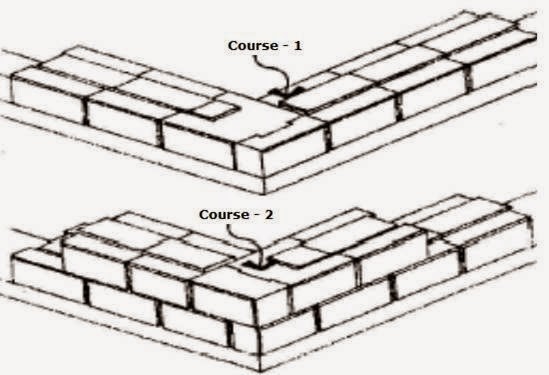

It is to be noted that the arrangement of these interlocking blocks should always start from the corner of the wall and proceeded. The corner blocks are preferred to be half blocks for better interlocking and to make it an integral part of the structure.

Project in India Build Using Mortarless Interlocking system

Some of the projects built using this system are

- PWD office at Dhaula Kuan

- Ministry of social Welfare Buildings at Sikri, Ballabhgarh

- Earthquake resistant rehabilitation 6000 + houses projects, Gujarat.

- ASI Complex at Gujarat

- 1000+ cyclone resistant houses by CARE

Thus we can conclude that these interlocking blocks have a great scope in future and will pave way for a sustainable construction technique, but there are certain disadvantages because of which this system is unable to replace the conventional masonry they are,

- The bond patterns between the interlocking blocks are limited thus the structure becomes architecturally more restrictive (e.g. building of curved walls is difficult).

- The use of interlocking blocks without surface bounding or grouting is not recommended for human occupancy.

- If during the initial laying of blocks, deformation occurs then it will result in decrease in strength for the whole structure.

- Since the technology is relatively new, it requires proper dissemination strategy.

- Even with the greatest care in assembling the walls, the joints may not be entirely resistant to wind and rain penetration. This makes the system less desirable.

– Hemalatha Sekar

(+91) 7249196273

(+91) 7249196273